1. Think about if you really need extra filtration.

HEPA filtration is great for allergy sufferers, but the general public has survived centuries without the product.

Normal filters screen out troubling particles, just not quite as intensively. They tend to be less expensive and (depending on the style) reusable.

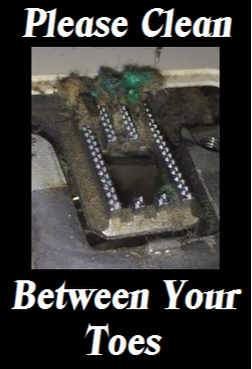

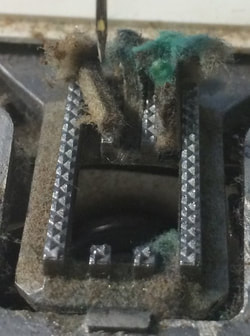

2. Keep your vacuum bags changed or (for bagless) dirt cup clean.

If you do need HEPA filtration, take care of the filter to prolong its usefulness.

HEPA filters screen the exhaust air from your vacuum, so the best way to sustain them is to keep the rest of the machine clean. The air goes through the vacuum's bag and other filters before hitting the HEPA filter.

RSS Feed

RSS Feed