Several sewing machines that were not feeding (moving) the material well visited the store recently. Something seemed to be slipping.

Theories ranged from the presser foot being worn out to the pressure on the foot being too loose.

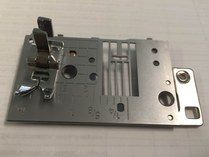

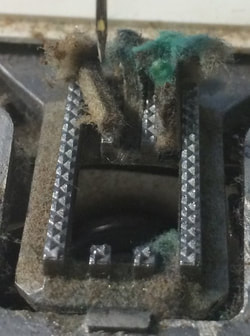

However, taking off the presser foot and needle plate revealed the truth...

One machine this month had so much felt between its toes that the reverse button was banging while the machine was operating!

To repair this situation, remove the needle plate and use a safety pin or stiletto to extract the compressed lint from between the toes of the dog feed.

Be careful not to drop the felt into the machine.

When your machine is clean and happy you'll be happy too!

RSS Feed

RSS Feed